Many times we find that there is a tool missing in our everyday life. Then at one point we think something like “Great, I’ll invent this tool and start selling it and my life will be full of sunshine and success“. At this point great work usually starts.

When we are thinking to start with a product, there are many things to evaluate before putting expensive time and other resources to work. In following I will explain a simple skeleton of actions and considerations.

We are loaded with power and want to act now.

It will be fun to do the tasks we are best of. But we need to do something else first. We need to visualize the situation where we are when the product is ready and starts selling. Who are the customers, how do we reach them. For sure setting up a page on the web will not direct the customers to us. Search engines will maybe find our page but it will rather make no sales. We need to start at one point working on attracting customers. Some tasks of it we need to perform first. We need to get clever way to verify how much people like the idea. Be warned that in many cases we get feedback like “Great idea, I would need one!” and when we are ready and name the price and are hopeful that we get lots of sales, then the customers disappear. So, the minimum that we need to understand is:

- Where is the value to customers: Is it time saving, more income or less expenses? The time saving must end with more income somehow, because the cash-flow and profit from it is driven by the income. Time saving may end with less expenses for a task, but many times there is an employee who needs to be paid anyway. The end result can be lousier life for employee and not less expenses.

- Alternative values may be amusement or less trouble with some trivial tasks that annoy a lot. Example: “Where is my desktop calculator to calculate 127.23+94.34/3.5 ? Uh, it is again lost! “. Be careful about such values. The emotional values are hard to pinpoint and will change during the time we develop the product. Project like this should be rather fun side-story of our life. When it is somebody’s business to sell amusement products, then this development budget should be rather little part of future predictable sales profit of already existing products.

- Prestige values are where owner of our product or service will prove he’s or she’s position in our society. These will give us chance to sell at high price (it must be hard to get for others) and we also need to be part of the prestige itself. This is hard to catch but possible. Success depends also on how the message is offered and who is doing it.

- Impossible becomes possible. This is again very difficult to predict. Here we build new market, new services and new demand. Probably we need to find trace to higher profit, higher turnover for our customers or more fun and new experiences. In any case there is hard to get any feedback before we have something to demonstrate. For example when our invention allows to travel into nearby stars within few days, then the public interest and willingness to invest to see whats there may be huge.

- What is the price (E1) the prospective customers are ready to pay? This sounds jumping ahead of time, but is actually very important to start figuring out at the beginning. From it will depend also development expense. In many cases, the lower the initial price target estimate, the more expensive will be the development.

It is quite common, that we are unable to figure out the the clear price nor get the clear feedback. It is alarming sign that the product is not that important to existing customer. It does not necessarily mean that the product is doomed, but means that we have no fast track. For fast track we should be able to get order contract with customers that covers our initial need for finances. When we see analytically real sign that there is huge profit gain from saving expenses, huge possible demand around the world but no order contract, then we need to go hard way- find own finances, maybe find investors, share the property with other entrepreneurs, … For order contract we need to go through following analysis where we will make sure the price and delivery time.

All great, lets act now !

Well, almost. Now we are probably ready for asking estimates. First we need to start evaluating. The greatest uncertainty is that we can not produce the product at reasonably low price. Instead of jumping into interesting problems to solve, great user experience design, revolutionary mathematics and not yet seen electronics, we need to start estimating the production expense. It is obvious that when we do not manage to get production price cheap enough, then we will have price issue that will reduce our sales. Expense E will be sum of:

- D= Development expenses, these must be made before any sales starts. This will also include building first prototypes.

- C= Certification expenses.

- M= Materials for N items..

- A= Assembly of N items.

- S= Sales and promotion for X years.

- H= Delivery of N items.

- Q= Support and quality service expenses of N items.

Some expenses depend on the amount produced, like materials and assembly or delivery. So when we plan to sell the N items and provide support at least for X years from the sales, then the minimal price the prospective customers must be ready to pay is:

[math]E_1={{D+C+S}\over{N}} +{{M+A+H+Q}\over{N}}[/math]

I have collected the sum into 2 parts: first that does not depend much on the amount of products produced and the second that depends. Materials expense M will be higher when we need more materials. When we need two items instead of one, then the expense will be twice. When we need 1000 items instead of one then the expense might not be 1000 times higher than for one but 300 times higher. Development and certification expense at the same time does not depend on the amount, the expense stays almost the same. The good part is, that the more we produce, the less is development part in it.

I wrote that development expense is higher when the product must be cheaper. It is because to make the product become cheaper, alternative ideas need to be tested out. We need to check how cheaper parts may be used, how to reduce amount of parts. All the parts need to be tested, the functions of these methods need to be verified, calculations need to be optimized to run on cheaper and less powerful computer, to use cheaper battery the power consumption need to be minimized and so on. During the first phase of development, the product will be made using rather expensive parts to verify that it will work, is it pleasant to use. Later will some parts be replaced and many such iterations will be performed. You can see, that when the E1 can be rather high, then less price optimization iterations are needed.

How to find the different expenses and properties:

- What is the realistic time period X ?

- Take D+C around 100,000€ for simpler product, more for complex product.

- Select some advertisement channels and figure out S.

- Calculate: [math]N \geqslant 8 \times {{D+C+S}\over{E_1}}[/math].

- Is the N realistic? Is the N/X realistic? If not, ask for rough estimates, maybe development is super easy thus D is much lower or E1 can be higher. Repeat previous steps if needed.

- Make prototype candidate design,

- Find from catalogs, ask from suppliers what will be the material price M. Look for higher volumes too.

- Ask based on prototype drawings what will be the assembly price A to be, ask for some higher volumes too.

- Overestimate the quality to be pretty bad this time, [math]Q={1 \over 20}\times{E_1}\times{N}[/math].

- Use the re-sellers formula [math]H=N \times {E_1 \over {2}}[/math]

- Now we have all the formula, check that the second part is [math]{E_1 \over 8}\geqslant {{M+A+Q}\over{N}}[/math].

- If needed, do more investigations about the different prices, develop another prototype candidate and repeat the above steps until we will find satisfactory business model. Fine tune all the parts in the formula and find the evidence that these expenses are realistic. Document all of it.

Now we act, really.

After going through the previous steps, now we are ready to start spending resources into development. We have worked through different scenarios, checked different expenses from suppliers. And, we have some risk reduction methods. If the development will be more expensive, we must sell more products to get even. If the components appear to be too expensive for satisfactory goal, we have to raise the sale price of the product. We have options to reduce profit part if the product will not sell around the rate N/X, e.t.c.

If we do not have own resources, we need to start finding investors. When looking for investors, we need to prove our capability. We need to find what we can achieve to build ourselves to make our demo clear and understandable to investors. Then move on with new iterations.

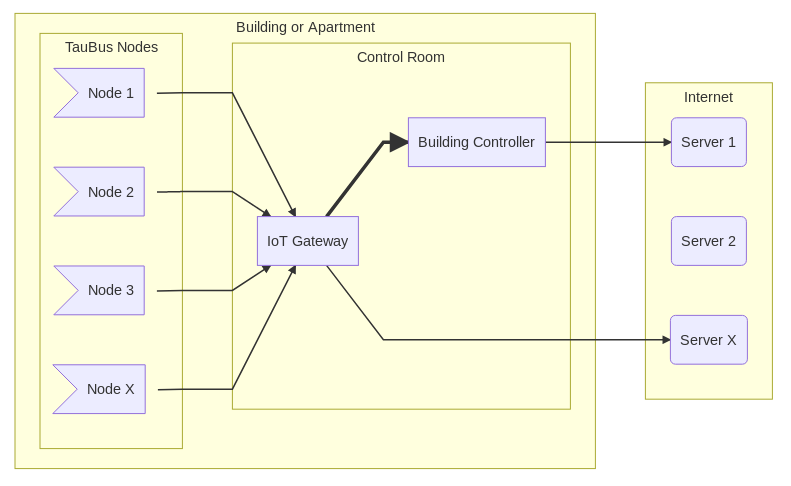

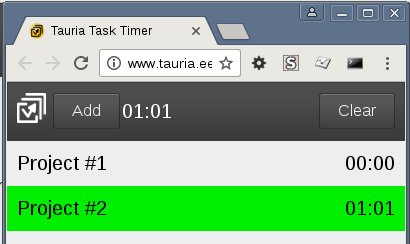

How Tauria can help?

As written above, the estimation is very complex task. It will be possible to cold-ask for estimations from different companies but in reality they are kind of afraid to make cheaper than needed proposals. Therefore the proposals will be rather expensive and leave you with feeling that the goal is impossible.

To get better estimations, investigation of different possibilities to find the model where all the expenses will fit into criteria, must be carried out. Also, user experience investigation will help you to get better view of what is the underlying need for the product. From there maybe something planned at first is not needed or will be achieved differently.

As an engineering company, we can help you with a full development cycle, as well as making cost estimations Feel free to contact us if you have any questions or need further information.

I admit that as of 2017 I still haven’t figured the sales part out

for myself, but the statements that I tend to believe to be settled as “true”

in my mind are:

x)

Steve Jobs got it right by stating that in customer surveys, where

customers are asked, what they would like to buy, the answer is always:

MORE THE THING THAT WE CAN UNDERSTAND (== only old tech) AND CHEAPER!!!

Anything brand new, innovative, is not yet known to customers, id est

try to find out, whether a medieval French king would like to buy a touch-screen

device, when he does not understand, what a screen is.

The price does not even matter in that case: one castle, two castles, 5 castles,

6 occupied/annexed islands…

x)

Potential market can be increased by making a product usable in

multiple, different, scenarios, while products can be differentiated

by making them more specialized.

There’s a controversy, yes, but it only appears to be controversial.

Namely, a special spoon for eating ice cream can be used in

bars, at home, on planes, on ships, at beach bars and the spoon

might also be practical at homes for getting jam from jars.

All of that, while the product, “spoon”, is at least thousands of

years old, meaning that our great-great-great grandfathers would have

been already “late to the market”.

x)

As described at the previous point: properly designed products

can never be “too late to the market”. Mobile phone manufacturers

like Nokia did have the issue that they needed to use factories with

humongous production capability to make sure that the new

models flood the GLOBAL market before their competitors can PRODUCE

their batch of the phones that have similar artistic design and features

and pace of the race was determined roughly by the fact that it

took about 1 year for designing and getting the production for new

models going. (Phones with new physical dimensions needed special

adapters to the robots that tested the phones at the end of the

production line. Those adapters and testing robots, hundreds of them,

literally truckloads, shipped all around the world with as air cargo,

were produced in Tallinn, by Jot Automation. I can tell about it, because

my NDA has expired and that business has gone to history like Nokia,

so no problem telling about it.) It’s fun to notice that the giant Nokia

had exactly the same problems and tactics that my Mother had

with her tiny-tiny handicraft business: it took her competitors about

1 year to start making copies of her designs and she intentionally

worked hard to make sure that she had new models every year, because

she knew that it takes about one year, usually the winter months, for

her competitors to produce their batch of clones. The trade fairs, where

she attended, were held a few times a year, may be 10 events annually

maximum, usually at nice, warm, summer months, one, “Luige laat”,

at early spring (and my Mother has skipped it sometimes due to weather).

So, all in all, the “too late to market” is really only an issue with “low tech”,

things that “any ape can use and understand”. Like, why would any

competitor want to clone a product, if they have to be convinced of

the usefulness of the product the same way clients need to be convinced?

Really, there’s no problem with competition in the space of truly new things,

no hurry, no “race to market”. Sales is harder, but the barrier of “seen as useless”

can be left up for competitors and broken down only with select clients that

one wants to work with.

x)

At the cost side, in stead of minimizing development work within a single product,

one should minimize the amount of development work across all projects.

That does entail that a single project can become more laborious, because

in stead of one-off hacks a library has to be designed and the API of the

library needs to be carefully though out, etc. But, if one works as a freelancer

and the opportunities are limited by the available development time, then

it’s a fine investment of one’s time.

Actually, as I said, I haven’t figured out a lot of things yet, but an archival copy

of my 2017_01, or, rather, 2016_12, version of my work process can be found from:

https://archive.is/qQGgA

Thank You for reading :-)

P.S. You might also want to look at

https://yalantis.com/blog/cost-services-europe-market-research/

Thanks for sharing such an informative post. Keep Sharing..